-40%

4Axis Closed Loop Motor NEMA34 6A 1700 oz.in 12N.m Encoder&Driver kits CNC

€ 360.09

- Description

- Size Guide

Description

Welcome to my storeThis item will be shipped from Germany by DHL or UPS to European Union Customers.

Attention:

All goods price include VAT.I will make invoice for every order.

If you have VAT number,don't forget give me your VAT number and company name after payment.

If you don’t have VAT number,you buy it directly,I will make invoice by your ebay address.

This item includes:

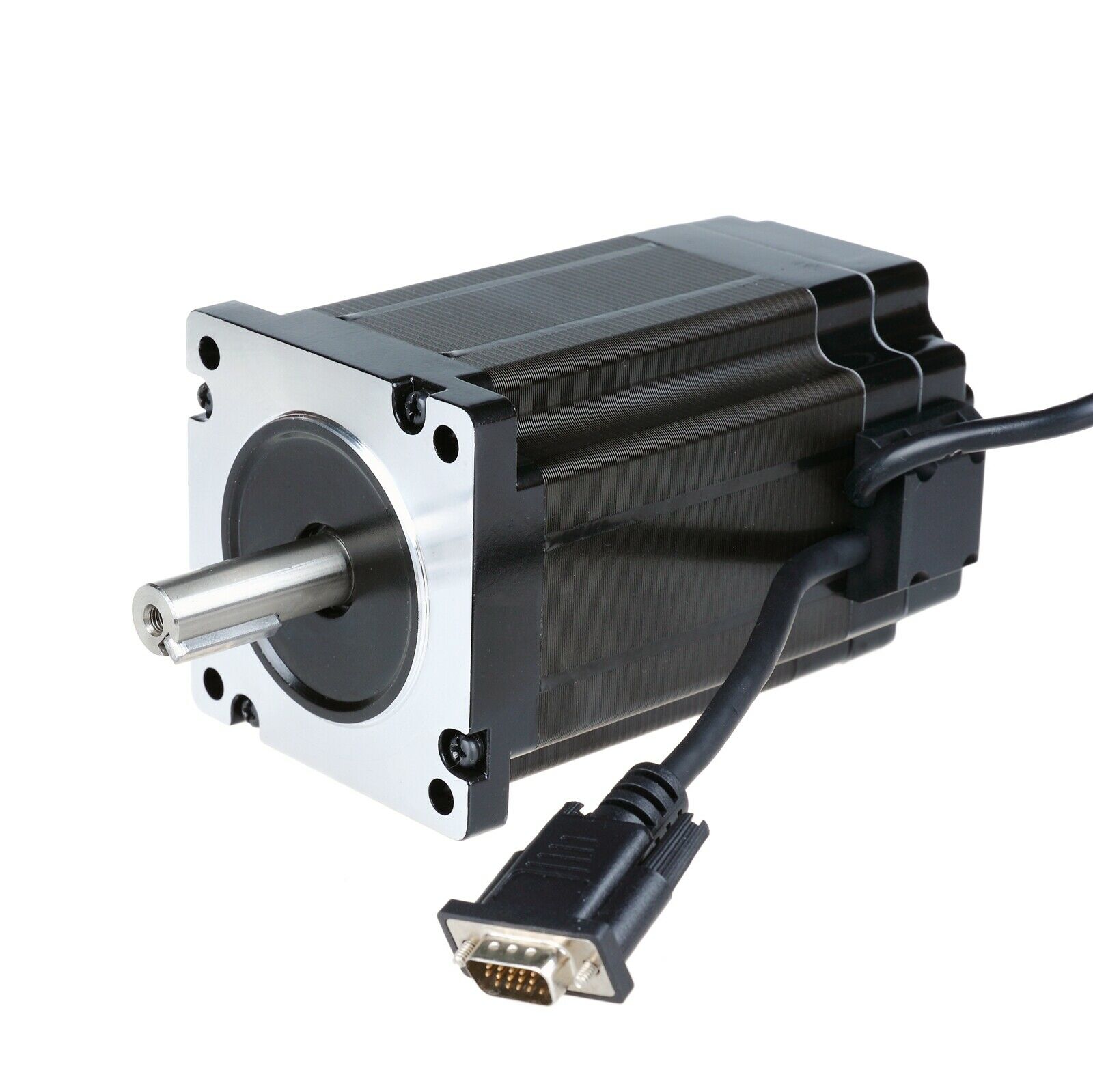

4 PC NEMA34

34SSM5460-EC1000

Closed-Loop Stepper motor 171MM 12n.m 1700 oz.in 6A

4 PC 3m cable

4 PC Closed-Loop Stepper Drive HBS86H

4 PC Power Supply 350W-60VDC

1 PC Breakout Board & 1 PC parallel cable

Detailed information:

1.

NEMA 34 Closed-Loop Stepper motor

34SSM5460-EC1000

Artikelbeschreibung

Item Description

34SSM5460-EC1000

Schrittwinkel

Step Angle

1

.

8 ± 5%

°/ Step

Spannung

Rated Voltage

3

.

60 V

Nennstrom

Rated Current

6

.

00 A /Phase

Widerstand pro Phase

Phase Resistance

0

.

55 ± 10%

o

hm/Phase

Induktanz pro Phase

Phase inductance

8

.

40 ± 20%

mH/Phase

Drehmoment

Holding Torque

1200 N

.

cm Min

≈ 1700

oz-in

Rastmoment

Detent Torque

24

.

50 N.cm Max

Drehmoment

Rotor Torque

3600 g- cm²

Auflösung

Resolution

1000

Wellendurchmesser

Shaft Diameter

Keyway Shaft=Φ 14

.

00± 0

.

012 mm

Keyway=5*5*25C

Motorlänge

Motor Length

171mm(Motor Length+Encoder Length)

Leitungsverbindung

(

Bitte sehen Sie das Bild

)

Wires Connection

(Please see the picture)

Motor Connection:

Black A+ ,

Red A-,

Yellow B+,

Blue B-

Encoder Connection:

PB- = Yellow,

PB+= Green

PA- = Black,

PA+= Blue

VCC=Red,

GND= White

Gewicht

Motor Weight

6.2

kg

2.

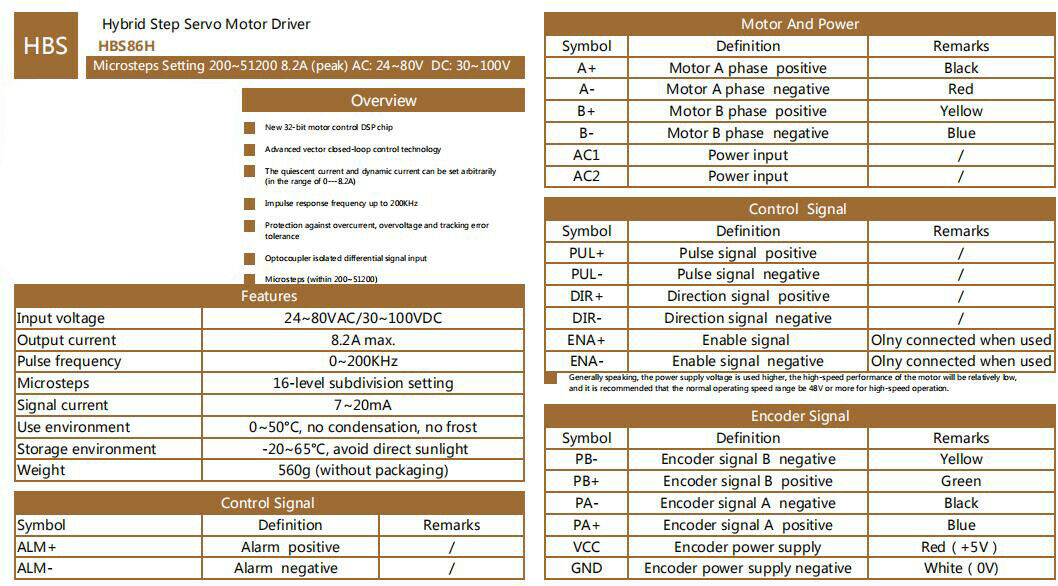

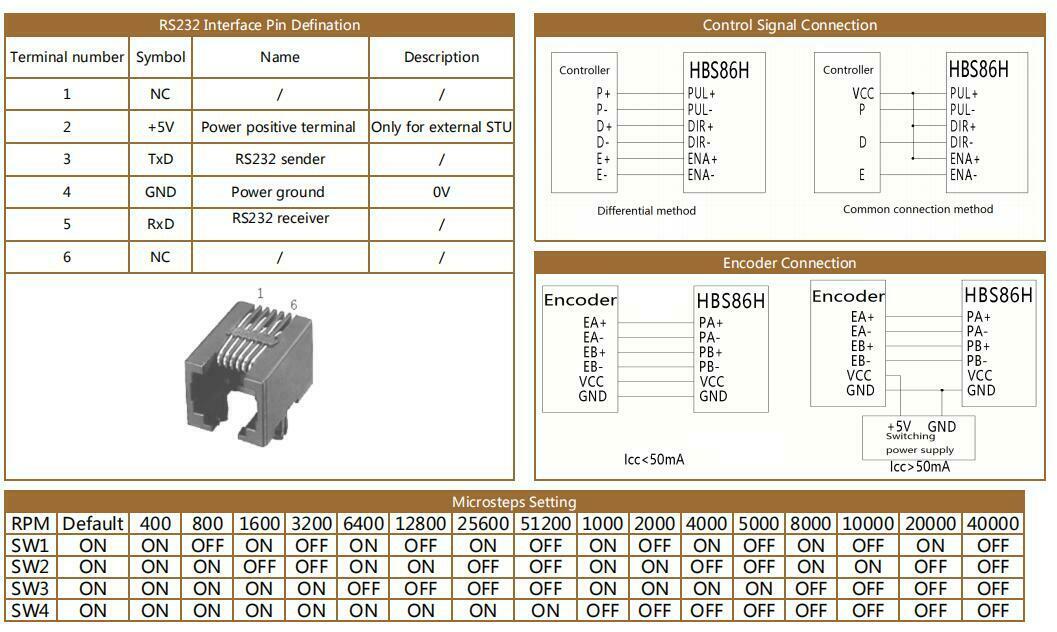

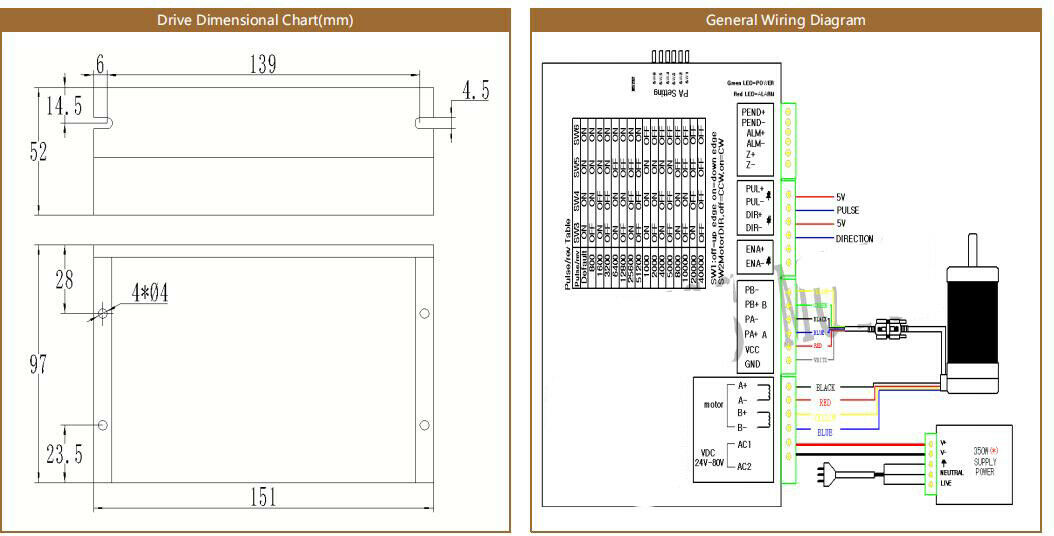

NEMA 34 Closed-Loop Stepper motor driver HBS86

Description

1.HBS series provides the requirements for high performance and reliability, when the servo is the only alternative to the selected application while it is still cost-effective.

2.The system includes a two-phase stepper motor all-digital, high-performance drive, which is used to close the real-time position, velocity and current loop servo system as internal encoder combined. It combines servo and stepper motor technology, and both offer unique capabilities and enhancements, but at a fraction of the cost of a servo system.

3.Its quick response and great features make it ideal for hunting does not apply, such as bonding and visual systems, including a short distance fast motion is required, hunting will be a problem. It is an ideal application by belt or other mechanism has a low rigidity and you do not want it to vibrate when parking.

Function

1.HBS86H 2-phase hybrid servo drive

2.36-100VDC/18-80VAC

3.No adjustment, simultaneous loss null

4.Closed circulation, eliminate the loss of synchronization

5.Broader operating range, higher torque and higher speeds

6.Reduced motor heating and more efficient

7.Smooth movement and low noise motor

8.Do do not require high torque margin

9.No adjustment and is always stable

10.Fast response, without delay, almost no settling time

In the standing start and low speed, high torque rigidity 11.High

12.Lower costs

Applications

The HBS series offers an alternative for applications requiring high performance and high reliability when the servo was the only choice, while it remains cost-effective. Its great feature of fast response and no hunting make it ideal for applications such as bonding and vision systems in which rapid motions with a short distance are required and hunting would be a problem. And it is ideal for applications where the equipment uses a belt-drive mechanism or otherwise has low rigidity and you don't want it to vibrate when stopping.

Typical applications

:

For a variety of small and medium sized automation equipment and instruments, such as: engraving machine, stripping machine, marking machine, cutting machine, laser machines, plotters, medical equipment, machine tools, automatic assembly equipment, electronic processing equipment. In user expectations low noise, high speed device applications particularly good effect.

3.Power Supply 350W-60V

Switching Power Supply 350W-60V, output 60VDC, input 115~230VAC 5.6A

4.Breakout board

Description:

• Built in DB25 male connector.

• DB25 Output Pin:P1,P2,P3,P4,P5,P6,P7,P8,P9,P14,P16,P17.

• DB25 Input Pin: P10,P11,P12,P13,P15.

• DB25 GND Pin: P18-P25.

• Power supply: +5V DC.

• Built in C-class Optical-coupler.

• High quality with Surface-mount Tech

P2 P3 is set to X-axis for the X-axis pulse

P4 P5 is set to Y-axis, Y axis pulse

P6 P7 is set to Z-axis Z-axis pulse

The other can be set to A B C axis

A-axis pulse P8 P9 is set as the A axis

P14 is set to B-axis B-axis pulse P1

P16 P17 is set to C-axis, C axis pulse

Can also be set to the spindle control signal \ electrical permit

Input interface for the P10 P11 P12 P13 P15

Additional instructions:

1.About VAT invoice:

Usually I will make invoice every Friday.

Now ebay doesn't show e-mail.If you want invoice,you give me your e-mail,I can send invoice to your e-mail

2.Delivery time:

All products are available and can be shipped out right after payment.

I only make ship on work day(Except Saturday、Sunday and Holiday).

- Shipping via DHL or GLS.

After delivery,for Germany,about 2~3 work days.

After delivery,for EU country,usually about 5~7 work days, if you not receive goods at the Eighth work day,you search the tracking on DHL or GLS website.If the tracking has problem,you make a call to your local DHL or GLS,then contact me .

3.Service:

If you need more pictures, descriptions, manual, please contact me.

If you have problem,when you connect it,you contact me,I will help you.

Application:

Our Stepper Motors are used on small to mid-sized CNC mills or milling machines, CNC lathes, Pick-n-place machines,Laser Engravers and Laser Cutters, Vinyl Sign Cutters, CNC Plasma Cutters, and CNC Foam Cutters. Carver machine ,Dispenser,Automazation,3D Printer,Stage lighting,instrument,laser

equipment,scanner Dispenser

,Logistics equipment,

and so on.These motors have been used in precision telescope positioning systems and robots.